1. Swing installation requirements are as follows:

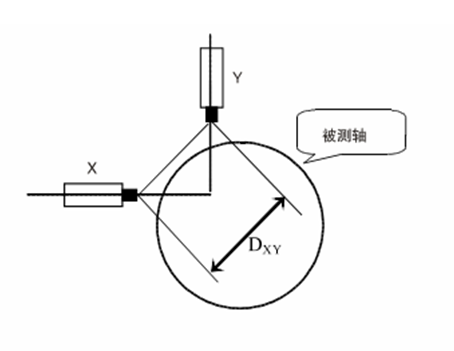

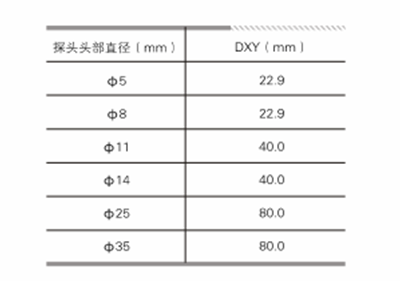

When installing the eddy current sensor, pay attention to the following problems: the distance between the probes and the installation distance between the two probes should not be too close, otherwise the probes will generate adjacent interference through the magnetic field, resulting in distortion of the measurement results. The installation distance should meet the dimension requirements in the table below.

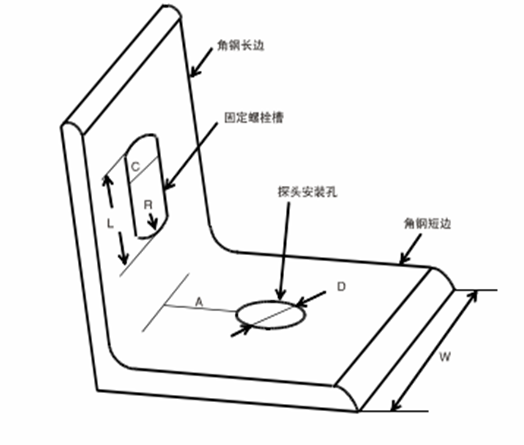

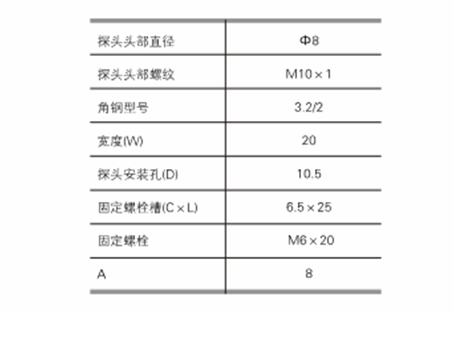

a . The eddy current sensor mounting bracket (probe diameter 8mm sensor) requires that the bracket has good rigidity and the strength is as high as possible, otherwise it will cause measurement errors due to the vibration of the bracket. The dimensions of the angle steel are shown in the table below.

b . The linear measurement range of the sensor and the change of the gap between the measured objects should be considered when the probe is installed. Usually, the installation gap should be set at the linear midpoint of the sensor. Usually the gap is about 2mm (standard 2mm). When the sensor and the monitoring instrument are correct After connecting, check that the gap voltage of the instrument should be within the range of 2v-3v, which is normal (standard 2.5V), otherwise the installation gap value should be adjusted. It can be viewed through the gap button on the meter (this function is only valid for the swing sensor)

When the gap is corrected to 2mm, the instrument LED should display 0.00, which is a proper state.

This instrument is equipped with a sensor range of 1mm far and near