1. Overview

MFK magnetostrictive liquid level transmitter is a high-precision and measurable ultra-long stroke position measurement transmitter developed by using the principle of magnetostriction, which can accurately measure the linear displacement of moving objects. Due to the non-contact measurement method, it has no wear, high reliability, high stability, long life and good environmental adaptability. A transmitter can be used to measure liquid level, displacement, speed, and has a very high cost performance.

The structure of magnetostrictive liquid level transmitter is composed of stainless steel casing (including measuring rod), magnetostrictive material (waveguide wire), movable floating ball (with magnet inside) and electronic components.

2. Application

There are two common applications of magnetostrictive transmitters:

A. Displacement measurement: Connect the magnetic ring and the moving parts and put them on the measuring rod to measure the displacement. Commonly used in hydraulic cylinder, cylinder piston position; machine tool positioning and displacement detection; wood processing, construction machinery; steam turbine, water turbine machinery; simulated motion platform; food processing, etc.

B. Liquid level measurement: Turn the magnetic ring into a magnetic floating ball for liquid level measurement. It is often used for liquid level height measurement of oil storage tanks or valuable chemical raw materials; multiple floating balls with different specific gravity can be installed on the same measuring rod to measure the liquid level of layered liquid in the same storage tank.

3. Working principle

When the displacement is measured, the electronic components of the transmitter electronics compartment generate an excitation pulse, which moves down the waveguide wire. There is a magnetic ring outside the measuring rod of the transmitter, and the magnetic ring moves along the measuring rod with the movement of the measured object. Because the magnetic ring will generate a magnetic field. When the magnetic field generated by the current is added to the magnetic ring to form a spiral magnetic field, an instantaneous torque is generated, which makes the waveguide wire twist and generates a tension pulse. This pulse is transmitted back along the waveguide wire at a fixed speed, and an induced current is generated on the receiving echo coil. The pulse, the return pulse, can accurately determine the position of the measured object by measuring the time between the start pulse and the return pulse and multiplying it by a fixed speed. Since the sensing element is non-contact, long-term online continuous measurement will not cause any wear on the sensor.

4. Technical indicators

Power supply: DC24V;

Power consumption: four-wire high-precision 35mA;

Working temperature: -20℃~+85℃

Range: hard rod 40mm~5000mm; retractable soft rod 50mm~20000mm;

Output form: 4~20mA; pulse signal; RS485 (digital communication);

Resolution: liquid level transmitter 0.2mm; displacement transmitter 0.2mm.

Accuracy: liquid level transmitter 0.5mm; displacement transmitter 0.3mm.

Dead zone: common type: upper dead zone, 50mm; lower dead zone, 50mm (can be appropriately changed according to user requirements)

Rod material: 304 or customized by the user

Electronic warehouse shell material: 304 or customized by users

Lead mode: 5-core connector, default length 5-core 2m;

Connection form: usually M18×1.5, or user special customization

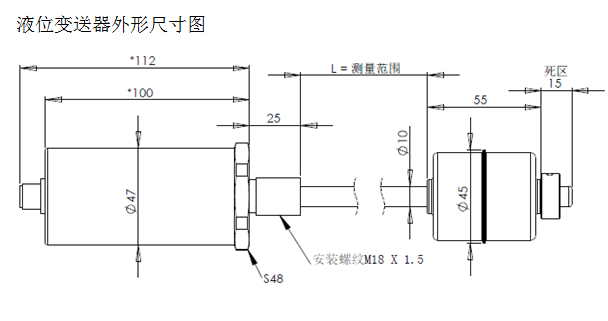

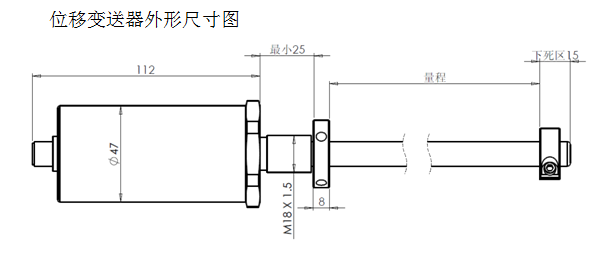

5. Dimensions

6. Precautions for use

1. Before ordering or installation, the user should first understand the installation site conditions, and carefully read the instruction manual, so that the ambient temperature, shock, vibration, pressure and size of the installation site meet the installation allowable range of the displacement transmitter. The purchaser or user Responsible for the application, corrosion protection and function selection of the product, and the ordered product should meet the requirements of the use environment;

2. The measuring rod cannot be bent. After use, the product should be put back into the packaging tube; the electronic parts or ends of the displacement transmitter are not allowed to be subjected to large shocks or vibrations.

3. The displacement transmitter cannot be directly used in flammable, explosive, corrosive, steam and liquid situations that have chemical reactions or other damage to the displacement transmitter. If necessary, protective measures are required to protect it.

4. The electronic components of the displacement transmitter are splash-proof but not submersible, and the liquid must not be immersed above the hexagonal base. After installation, the electronic warehouse should be protected.

5. The shielded cable of the displacement transmitter must avoid high-power power supplies, radio frequency signal sources and other noisy transmission lines.