1. Overview

LJZ-2 intelligent flow monitor is an intelligent digital instrument that processes standard signals with single-chip microcomputer as the core. It cooperates with three valve groups, differential pressure flow transmitter △P, etc. to form a flow monitoring device, which constitutes the differential pressure flow of the turbine volute. Monitoring System. The device can output corresponding analog quantity at the same time. When the flow exceeds the preset value, an alarm signal can be issued, with standard 485 communication. Carrying out flow monitoring can enable operators to understand the working conditions of the unit and optimize the operation of the unit.

2. Features

The intelligent monitoring device with single-chip microcomputer as the core processor has strong applicability.

Output the standard analog signal corresponding to the range.

Provides alarm status display and secondary alarm output contacts, and the secondary alarm value can be set independently.

It can switch to display instantaneous flow value and accumulated flow value.

With power-off protection, automatic memory function.

Perfect system self-check function.

The working power supply (+24V) of the transmitter can be provided.

3. Technical performance

Display mode: Eight-digit LED highlight digital tube display is clear and intuitive.

Output signal: standard 4-20mA output (load resistance≤525Ω)

Alarm output: Contact form: normally open contact.

Contact capacity: 5A/AC220V, 2A/DC30V.

Alarm setting: The second-level alarm value can be arbitrarily set between the upper and lower limits of the range.

Working power supply: switching power supply AC85~265V, DC110~340V.

Display range: Instantaneous flow value: 0~999999.99 m3/S

Accumulated flow value: 0~999.99999 Km3 /h

Power consumption: 10W.

The instrument provides a transmitter: DC24V power supply, the transmitter does not need an external power supply.

Environmental conditions: Temperature: Working temperature: 0℃~40℃.

Storage temperature: -25℃~+70℃.

Relative humidity: ≤85%RH.

4. Working principle

The flow through the turbine is measured by the volute differential pressure method, and the flow value of the turbine is calculated according to the relationship between the flow rate Q and the pressure difference △P between the inside and outside of the flow measuring section of the volute: Q=K√△P, where the K value is Volute flow coefficient.

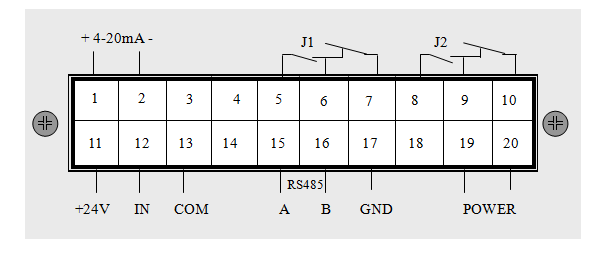

5. Terminals

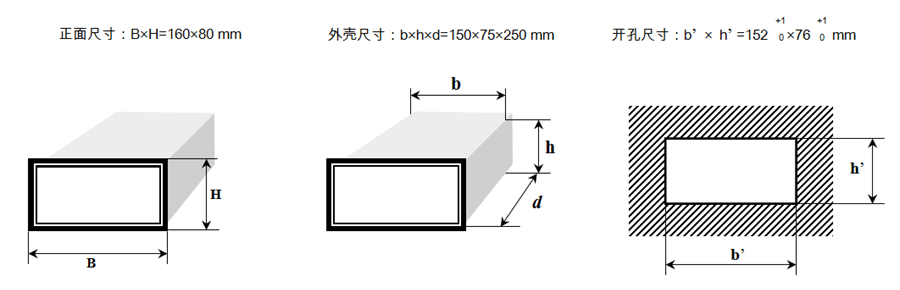

6. Installation size

The appearance of the instrument and the size of the opening are shown in the following figure: