1. Overview

WKD liquid level transmitter controller adopts imported micro-range dry ceramic pressure sensor to measure liquid level. The instrument integrates precision acquisition, on-site display, 4~20mA output, on-site alarm, and industrial communication as a standard liquid level controller, and can send out 6 sets of alarm signals. The alarm value is adjustable within the full range, and can be used for water level. , Oil level, such as bearing and oil return tank system level measurement.

2. Features

The appearance is small and beautiful, which is convenient for on-site installation. There is no traditional floating ball and no problems such as sticking and sticking.

The use of special acquisition chip makes the display more stable and reliable, with high accuracy.

The single-chip microcomputer can intelligently process the value, and the 6-level alarm contact output,

One standard industrial 4-20mA output, which has a linear correspondence with the actual liquid level.

The full-scale range of the 6-level alarm value can be set arbitrarily.

The nature of the 6-level alarm can be set arbitrarily.

The software has built-in standard MODBUS communication protocol.

Power supply optional: AD/DC220V or DC24V power supply.

High-brightness LED is used as the man-machine interface, and parameters such as liquid level and alarm are clearly visible.

The dry-type ceramic pressure sensor originating in Germany is selected, which has high overload capacity and strong anti-interference ability.

3. Technical performance

Measuring range: rod type Max 2000mm, Min 200mm;

The cable type can be customized between 2 meters and 200 meters.

Power supply voltage: AC220 or DC24V, to be determined when ordering.

Relay contact capacity: 0.3A/220VDC, 1A/30VDC, 6 groups of relays can be set

Display: 4-digit LED Accuracy: ±1mm, annual drift <±0.2FS

4~20mA transmission current Accuracy: ±0.5%, annual drift<±0.2FS

Standard MODBUS communication protocol (ordering instructions are required).

4. Working principle

The liquid level change directly acts on the front surface of the ceramic diaphragm, and the diaphragm electrode converts the pressure change into a proportional voltage signal output, which is sent to the A/D conversion circuit and to the microprocessor interface. The microprocessor accurately measures the frequency change and converts it into a digital signal corresponding to the pressure and stores it in the memory unit. The digital pressure value is displayed after scale conversion, and is compared with the set alarm value for alarm processing. The processor outputs a D/A voltage signal corresponding to the pressure, and then converts and outputs a 4~20mA current value.

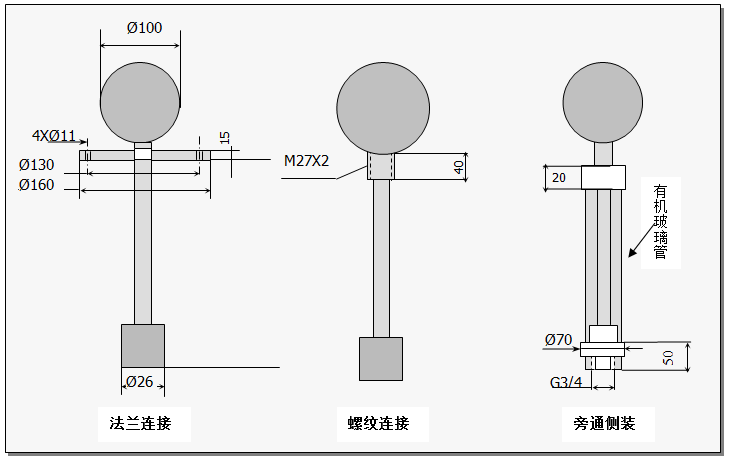

5. Installation form and size

WKD liquid level transmitter controller has three installation forms. The oil level monitoring of the fuel tank is mostly flange connection or threaded connection, and the bearing oil level measurement is mostly bypass side mounted.

6. Terminals

Please pay attention to confirm that the power supply voltage level of the instrument is ADC220V or DC24V, so as not to burn the instrument! If you are not sure, please call the manufacturer for consultation.

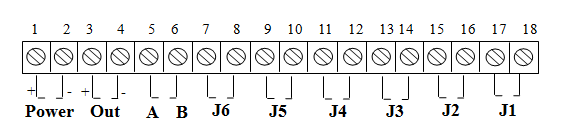

(1, 2) are Power power input ports (when DC24V power supply, 1 terminal is positive, 2 terminal is negative).

(3, 4) are standard analog 4-20mA output (terminal 3 is positive, terminal 4 is negative).

This instrument comes standard without communication, if you need communication function, you need to inform it when ordering.