1. Overview

The intelligent pressure transmitter controller is an all-electronic structure. Using dry ceramic strain pressure sensor, it integrates pressure measurement display, output 4~20mA standard analog quantity, relay control, and 485 communication functions. Accurate measurement of pressure. <85℃

2. Features

With high-performance single-chip microcomputer as the core control component, it has good reliability and anti-interference;

The use of special acquisition chip makes the display more stable and reliable, with high accuracy.

This product has the functions of LED display, analog output and relay contact output, and has the characteristics of wide application range and convenient application.

With standard MODBUS 485 communication.

AC / DC power supply system.

The highlighted LED is used as the man-machine interface, and the pressure value and device status are clear and intuitive

3、 Technical performance

Measurement range: - any range within 0.1 ~ 25MPa, and the pressure value higher than 25MPa can be customized.

Measurement accuracy: accuracy: ± 0.5% or accuracy: ± 0.25% annual drift <± 0.2fs

Digital display mode: four digit LED display

Output signal: 6 groups of relay contact output, alarm mode: upper and lower limit alarm, a group of standard analog quantity, and 6 groups of relays, one RS485 communication.

Contact capacity: 0.3a/220vdc, 1A / 30VDC (resistive load)

Contact type: DPDT

Operating environment: ambient temperature 0 ~ 50 ℃, relative humidity < 95%

Power supply voltage: AC 90-260v switching power supply or DC24V power supply (optional by the customer)

Outer diameter: radial Φ 100mm meter, axial with front edge (installed on cabinet)

Output current: 4 ~ 20mA transmission current

Power consumption: 10W

4、 Working principle

The pressure changes in the industrial process directly affect the front surface of the pressure diaphragm. The diaphragm electrode converts the pressure change to a proportional voltage signal output, which is sent to the frequency / voltage conversion circuit and sent to the microprocessor's counting interface. The microprocessor accurately measures the frequency change, converts it into a digital signal corresponding to the pressure and stores it in the memory unit. The digital pressure value is displayed after scale transformation, and the alarm is processed after comparing with the set alarm value. The output voltage of the processor corresponds to the output voltage of 20mA / D ~ 20mA / d. The parameters in the transformer controller can be modified and saved by pressing the key to set the interface unit.

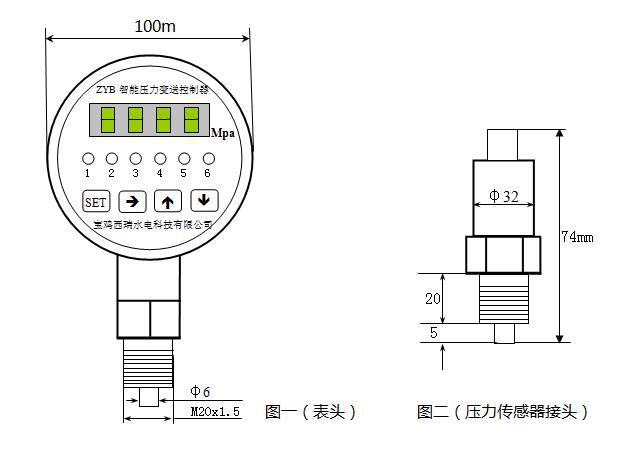

5、 Overall dimension

The installation dimensions of the device are fully compatible with the spring mechanical pressure gauge, and the seal can be tightened according to the corresponding installation procedures.

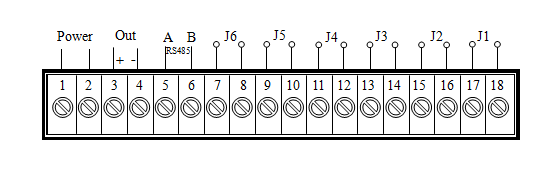

6、 Terminal block

Please pay attention to confirm that the power supply voltage level of the instrument is adc2v or DC24V to avoid burning the instrument! If you are not sure, please call the manufacturer for consultation.

( 1 , 2 ) are Power power input ports ( 1 terminal is positive and 2 terminal is negative when DC24V is powered ) .

(3, 4) are standard analog 4-20mA output (terminal 3 is positive, terminal 4 is negative).

If you need to calibrate the pressure gauge on site, please call the manufacturer for operation instructions.