1. Overview

The displacement transmission controller adopts imported rotary encoder as the core measurement device, supplemented by transverse force spring mechanism and peripheral intelligent circuit, which has many advantages such as high measurement accuracy, reliable performance, convenient installation and adjustment, and intuitive display. It is a series of products with high precision and high applicability developed by measuring the stroke of the relay and the relay. It can also have the functions of displacement sensor, master switch, display instrument, etc. It can display the displacement stroke and opening percentage at the same time. Eight channels can be set arbitrarily. Alarm output, with analog output at the same time.

The measuring rope of the opening displacement transmission controller can be directly fixed on the push-pull rod of the relay to measure the stroke.

2. Features

With imported rotary encoder as the core measurement device, the measurement is accurate and reliable.

The CPU directly collects the Gray code output by the encoder without A/D conversion error.

The two display modes of percentage and actual value can be switched between each other.

The transmission controller has powerful and complete functions, can output analog quantity, eight pairs of switch quantity and has a digital tube for visual display.

Compact structure, flexible and convenient installation. With standard MODBUS 485 communication.

3. Technical performance

Measuring range: 0~3000mm set according to user requirements

Working voltage: DC24V, ADC220V

Display mode: n% percentage and actual stroke value (switchable)

Output current: 4-20mA (two-wire system)

Output contacts: eight groups of relay contacts

Contact capacity: 0.3A\220V DC , 1A\30V DC

Accuracy: 0.5%

Working temperature: -10~65℃

4. Working principle

The WYS-2-W type displacement transmitter controller is connected to the measured body through a highly flexible stainless steel core wire, and is connected to the sensor shaft through a constant force spring to convert linear motion into rotational motion. The built-in precision circuit of the sensor performs reliable It can output the analog output (4~20mA) which changes linearly with the linear displacement.

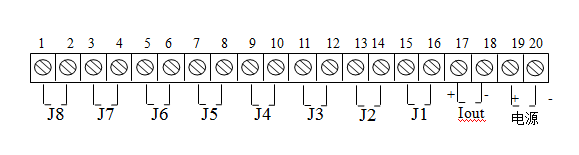

5. Terminals

19 and 20 are power input, and the voltage level is DC24V (terminal 19 is connected to positive, and terminal 20 is connected to negative).

17 and 18 are standard analog 4-20mA outputs (terminal 17 is positive and terminal 18 is negative).