1. Overview

The ZWB intelligent temperature transmitter controller adopts an all-electronic structure and is equipped with Pt, Cu and other thermal resistances to sense the temperature of the medium. It integrates three functions: temperature measurement and display, temperature 4~20mA transmission, and relay contact control output. Various temperature < 85 ℃, weak corrosive gas, liquid temperature measurement and control.

2. Features

This product has the functions of LED display, analog output and relay contact output, and has the characteristics of wide application range and convenient application.

The signal converter part is encapsulated into a module with epoxy resin, which has the advantages of anti-vibration, corrosion resistance, moisture resistance, etc., and can be used in places with poor conditions, which improves the stability and reliability of product application.

The intelligent processing unit adopts a high-precision temperature/voltage conversion circuit and a highly integrated embedded microprocessor, which has the characteristics of high measurement accuracy.

The parameter settings such as alarm and temperature compensation are directly operated on the controller operation panel, which is more flexible to use.

3. Technical parameters

Measuring range: measurable 0~150℃

Power supply: AC220V or DC24V

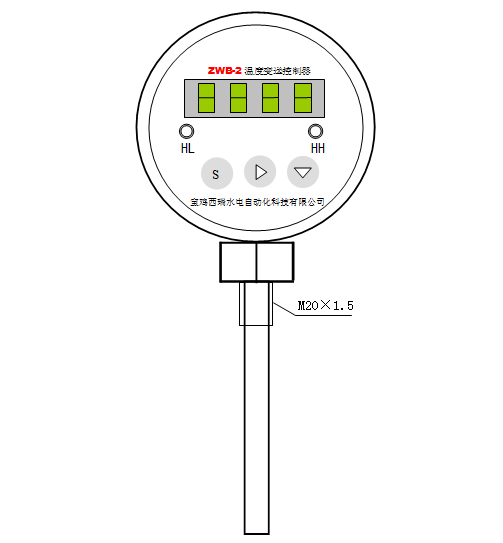

Parameter display: four-digit LED display window

Output signal: 1-way 4-20mA and 2-way switch value

Relay capacity: 5A/AC250V

Power: 10W

Application environment: if corrosive liquid or gas; medium temperature≤180℃; ambient temperature, 0~70℃; ambient humidity≤90%RH.

4. Working principle

The thermal resistance encapsulated in the stainless steel protection tube senses the temperature change in the industrial process, and converts the temperature resistance change into a proportional voltage signal output. After the voltage signal is processed by a high-precision circuit, it is sent to the microprocessor for A/D conversion. . The converted digital signal is stored in the memory unit. The digital temperature value is displayed after scale conversion, and is compared with the set alarm value for alarm processing. The processor outputs the D/A voltage signal corresponding to the pressure and then outputs 4~20mA current value through V/I conversion. The parameters in the controller can be modified and saved through the button setting interface unit.

5. Panel description