1. Overview

YHS-2 oil mixed water monitoring device is used to monitor the water content in the oil system of hydropower stations, thermal power plants and large pumping stations. When the water content in the oil tank and oil pipeline exceeds the alarm setting value, an alarm signal will be issued to remind the on-duty personnel to check the system in time to ensure the safe operation of the generator set.

2. Features

Accurately measure the moisture content of the oil system, and can output the standard analog signal corresponding to the display.

The alarm value can be set arbitrarily, and the adjustment is convenient.

The measurement principle is advanced, and the work is stable and reliable.

The sensor takes the microcontroller as the core to realize intelligence.

The product is small in size, full in function and easy to install.

3. Technical parameters

Power supply: AC220V±10% 50Hz

Measuring range: 0~5%

Measurement accuracy: 0.5%

Alarm setting: The alarm value can be continuously adjusted within the range of water content. When the moisture content reaches the alarm setting value, the light-emitting tube on the panel lights up, and the alarm relay contacts act simultaneously.

Signal output: Analog: DC4~20mA (load resistance≥525Ω)

Alarm contact output: each group of normally open and normally closed

Contact capacity: 10A/AC220V or 5A/DC30V

Power: sensor, 5W; meter, 10W.

4. Working principle

The device is composed of capacitive sensor and monitoring instrument. The capacitive sensor consists of inner and outer electrodes (equivalent to two plates of a capacitor) and a circuit part. When the oil penetrates into water, the capacitance value formed by the inner and outer electrodes changes significantly due to the great difference in the dielectric constants of the two. The sensor circuit generates a stable amplitude high-frequency square wave. When the capacitance value changes, the frequency of the square wave changes. After processing and amplifying the signal, the sensor outputs the corresponding current signal.

The monitoring instrument adopts the intelligent digital circuit with the single chip as the core. The current signal sent by the sensor is sent to the high-precision V/F conversion chip after low-pass filtering, shaping and amplification, and then sent to the single-chip timer. The single-chip computer counts and calculates it, and outputs it to the display circuit through the serial port, and the moisture content is visually displayed by a 4-digit digital tube. At the same time, the parallel output of the single-chip microcomputer is converted into a standard analog quantity by a D/A conversion chip for computer monitoring. The monitor has powerful memory software, and the alarm value can be set arbitrarily within the full scale by pressing the button. When the moisture content exceeds the alarm setting value, the relay will act, and the LED on the panel will emit light. At the same time, the monitor also provides the sensor working power.

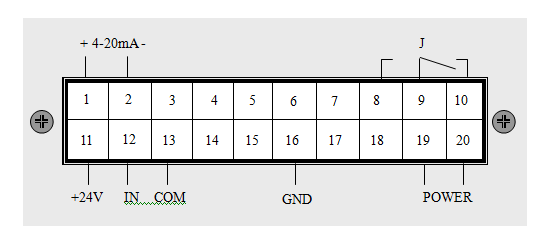

5. Terminals

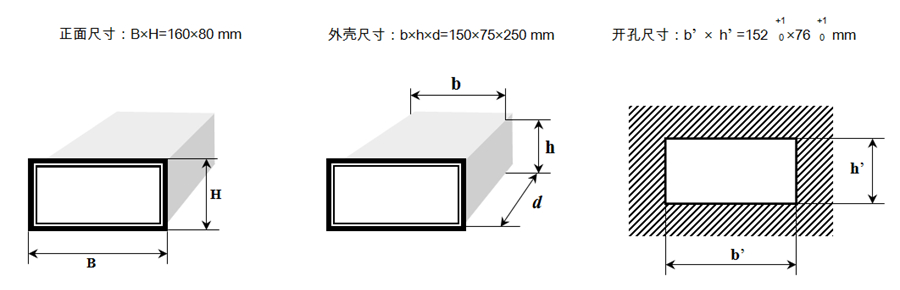

6. Installation size

The appearance of the instrument and the size of the opening are shown in the following figure: